Quartz halogen heaters are instantly effective making them ideal for heating intermittently used work stations

Heating Distribution Centres

The very scale of distribution centres presents a significant issue when considering an appropriate heating system. Distribution centres tend to be vast buildings occupied by a relatively small number of people. For this reason, conventional space heating is often considered impractical.

Should there be a requirement to provide a conventional space heating system for a distribution centre, a combination of industrial fan heaters and destratification units will be required. Please see Heating a Warehouse for details.

Spot Heating

The most common approach to heating a distribution centre is to provide localized ‘spot’ heating for personnel. For example, this approach can provide comfort heat for a person working at a packing station without the need to heat the surrounding area. The difference in operating costs, between space heating and spot heating can be extremely significant.

Quartz heaters heat people directly not the surrounding air

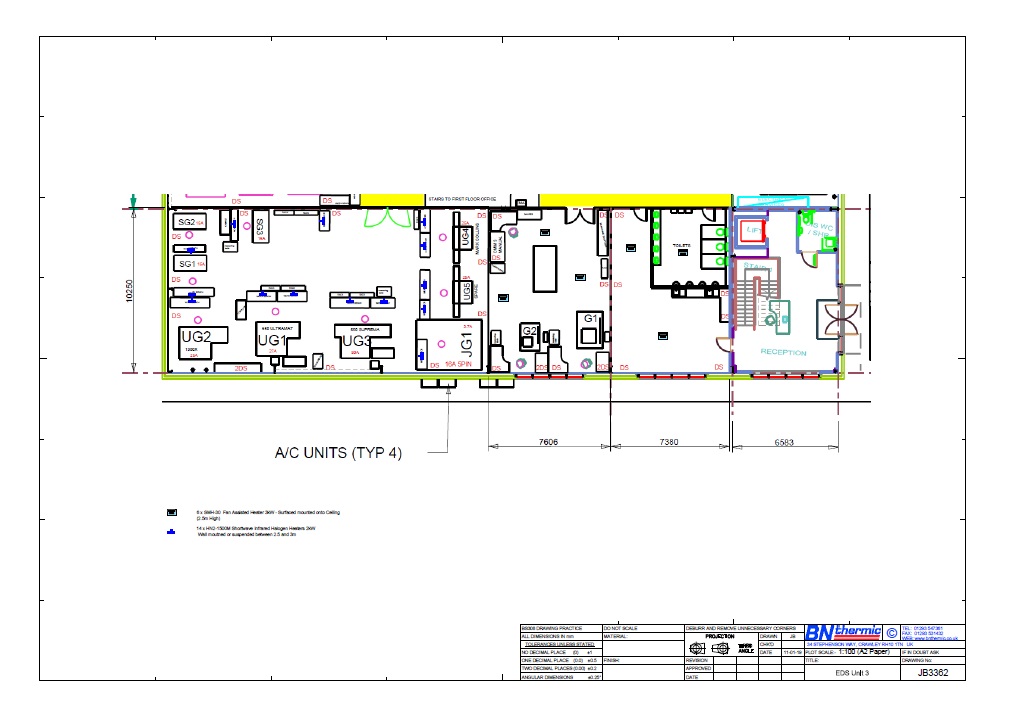

BN Thermic quartz halogen heaters come in 5 different outputs. Above is the 3kW two lamp version

Quartz Halogen Heaters

The heaters best suited to spot heating are quartz halogen heaters which heat people directly rather than the surrounding air. Quartz halogen heaters are instantly effective, a feature that keeps pre-heating to a minimum and means that there is rarely a requirement to heat an unoccupied workstation.

Heater Selection and Positioning

Typically, a quartz halogen heater would be mounted above a workstation at around 2.5m. An individual packing station might require a single 1.5kW heater while a larger bench might require a combination of larger output heaters.

Quartz heaters can be wall mounted using the bracket provided. Suspension kits are available for drop rod/chain mounting

Controlling individual work stations keeps running costs to an absolute minimum

Control for Economy

To maximise the cost savings of a spot heating approach, the selection of suitable control devices is vital. It is rarely sufficient to rely on personnel to switch heaters on and off as required. Two types of controller should be considered.

A movement senor will automatically switch on a heater when movement is detected. BN Thermic’s movement sensor can be programmed for time delay of up to 18 minutes and if no further movement is detected within the selected period, the senor will switch the heater off.

An alternative is a push button timer. This type of device works in a similar way but requires somebody to push a button on the front face of the timer to switch on a heater.

We strongly recommend the use of either a movement sensor or a push button timer for controlling spot heaters in a distribution centre.

Designing a Spot Heating Scheme

To design a successful spot heating scheme, an understanding of the size of a heater’s ‘footprint’ and the optimum heat intensity for a specific activity is required. The engineers at BN Thermic have considerable experience with this type of application and are always available for consultation.

BN Thermic engineers can design schemes for any sized project