Energy-Efficient Heating Upgrade for CK Tools Head Office North Wales

Project Type

Warehouse/Factory Heating

The Project

In this case study we look at a large industrial infrared heating installation from by our friends at CHIL Electrical & Renewables. Their customer, CK Tools, operates a large warehouse facility and are actively working toward achieving net-zero carbon goals. As part of CK’s sustainability plan, they sought to replace an outdated oil-fired heating system that was no longer reliable, efficient or supported by available spare parts. Here’s how it all unfolded.

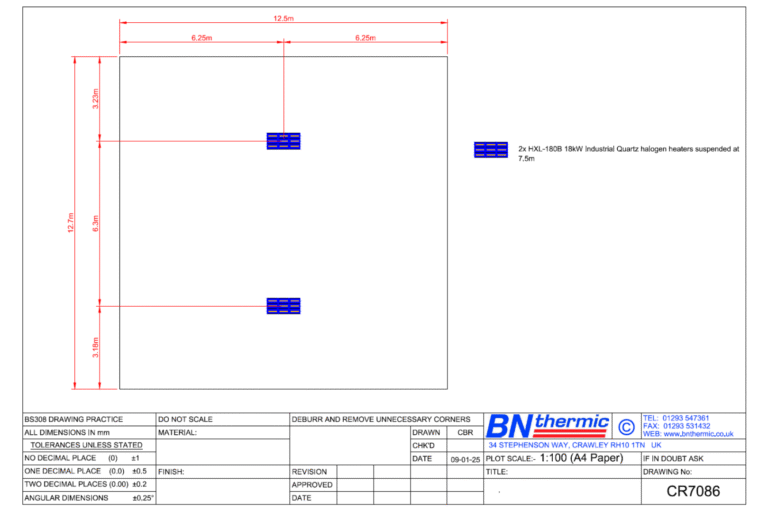

HXL quartz heaters providing instant comfort heat from a 7.5m mounting height

Project Summary

CK Tools approached Chil Electrical & Renewables to design and install a new heating solution for their warehouse. The initial request was for a full warehouse heating system. However, following a detailed site assessment and power-usage analysis, we identified a more efficient, cost-effective alternative that better aligned with both their operational needs and electrical capacity.

The project threw up a few challenges including:

• The existing oil-fired heating system was obsolete and needed full decommissioning.

• The warehouse’s electrical supply did not have the capacity to support a full building heating system.

• The facility required a targeted solution that supported staff comfort without unnecessary energy usage.

The Approach - Site Visit, Data Logging & an Optimised Heating Strategy

During Chil Electrical’s initial assessment, they installed a data logger to analyse real-time energy capacity and usage. This confirmed that the existing supply could not support a full electric heating system across the entire warehouse. The analysis also showed that heating the full warehouse was unnecessary as staff spent most of their time in designated working zones, such as packing areas and sorting areas.

Working with Chil Electrical’s data and dimensions, we then designed a scheme to provide focused heating where it was genuinely required – improving comfort while significantly reducing energy consumption.

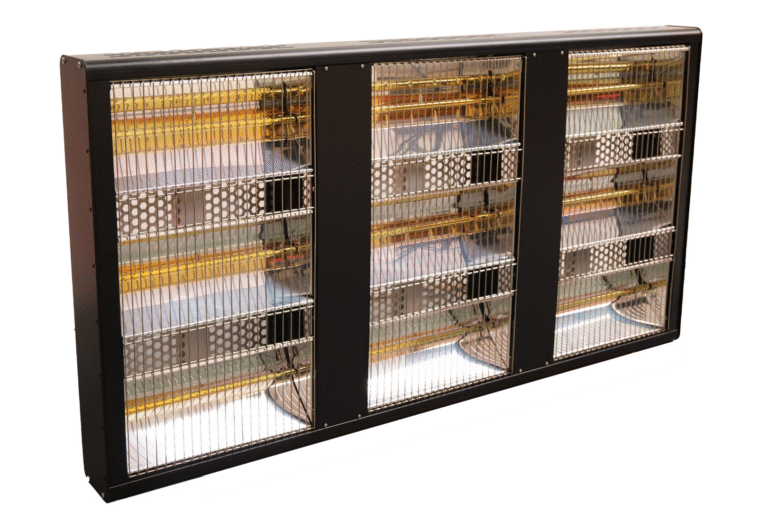

The Heaters

We specified 2 x 18kW HXL quartz halogen heaters to be suspended form the ceiling at 7.5m. Quartz halogen heaters provide instant comfort heat making them ideal for intermittently used areas like pick and packing stations. Because they heat people rather than the surrounding air, they are also highly effective for spot-heating specific work areas within larger, unheated premises.

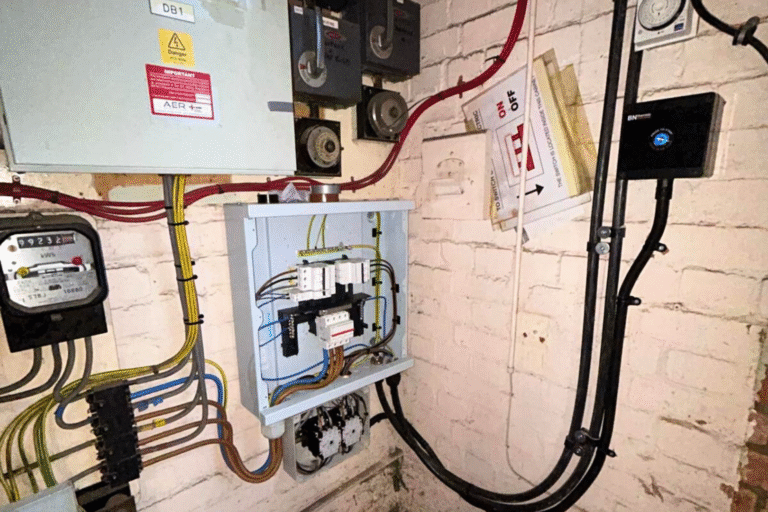

To prevent heaters from being left running unnecessarily, the team at Chil Electrical installed TS-8 push button timer switches. This ensures heaters operate only when required, supporting CK Tools’ energy-efficiency and cost-reduction aims.

Electrical Infrastructure Upgrade

To safely support the new heating equipment, Chil Electrical also installed a new 3-phase distribution unit. The original installation was outdated and had no spare capacity, so an upgrade was essential for compliance and reliability.

A great photo displaying the TS-8 timers, the new distribution board and the contactors working together

A Successful Project

Overall the project was a big success. George and his team at Chil Electrical were able to meet their customer’s requirements by achieving the following:

• Improved staff comfort in key working areas

• Reduced energy usage compared to heating the full warehouse

• A future-proof electrical infrastructure ready for ongoing efficiency improvements

• A solution aligned with CK Tools’ net-zero targets

• Reliable, modern equipment replacing obsolete oil-fired systems

We’d like to personally say a big thank you to George and his team for trusting us with the design work and for supplying us photos of their completed project.

Related Case Studies

Industrial Fan Heaters Installed in a Manufacturing Facility

Project Type: Warehouse/Factory Heating

Location: Derbyshire

Industrial Fan Heaters Installed at BN Thermic Ltd

Project Type: Warehouse/Factory Heating

Location: West Sussex

Industrial Fan Heaters Installed at Allon White Sports Cars in Cranfield, Bedfordshire

Project Type: Warehouse/Factory Heating

Location: Bedfordshire