Heating for Warehouses

Warehouse heating systems are required to provide an acceptable working environment, and/or to protect product from the adverse effect of cold temperatures.

Generally, the requirement is for a simple, reliable, no frills system that operates trouble-free year after year. Simple control systems are also required to ensure that the key heating objectives are met with the minimum consumption of electricity.

Industrial Fan Heaters

Because warehouses tend to be full of racking, fan assisted heating systems are generally preferred to radiant systems as they encourage the circulation of warm air between and through the racks. A warehouse will lose heat through the fabric of the building as well as through ventilation, especially through opening doors etc. A successful fan heating system must have sufficient total kW output to offset these losses and sufficient air circulation to ensure an even air temperature throughout the warehouse.

BN Thermic industrial fan heaters are hand assembled in the UK and backed with a 5 year warranty

BN Thermic industrial fan heaters are be easily wall mounted or suspended on chains

Controlling Industrial Fan Heaters

BN Thermic has developed the OUH2 industrial fan heater specifically for this kind of application. In a large warehouse a number of fan heaters will be installed and evenly distributed. Normally temperature control is provided by the heaters’ built-in thermostat. This means that in effect the heaters will operate individually perhaps responding to a localised drop in temperature resulting say from a roller shutter door opening. The heaters can however be linked in a control daisy-chain to a single programmable timer, on/off switch and/or frost thermostat if required.

Click here for full details of BN Thermic’s industrial fan heaters

Destratification Units

A major problem when heating taller building is a phenomenon known as temperature gradient. It is estimated that air temperature increases by around 2.5°C for every metre above floor level. Therefore, to maintain an air temperature of 20°C at floor level, in a 6m high warehouse, the air temperature at ceiling level would be around 35°C. The net result is a large body of over-heated air that is expensive to generate and serves no useful purpose.

Destratification units save up to 30% off an annual heating bill

Destratification units are hand assembled in the UK and designed for years of maintenance free operation

Energy Saving

BN Thermic strongly recommends the use of destratification devices in warehouses where the ceiling height exceeds 4m. This type of device will sense when there is a differential between air temperatures at low and high level and use a powerful fan to reduce the differential. The use of destratification devices can reduce running costs of a warehouse heating system by up to 30%.

Click here for full details of BN Thermic’s destratification units

Quartz Halogen Heaters

In some warehouses conventional space heating is just not practical. In these circumstances, there is often a requirement to provide localised heat in specific areas for example a packing area. We call this spot heating. The best means of spot heating a target area within an otherwise unheated warehouse is a halogen heater. This style of heater emits shortwave energy as well as a warming red glow.

This energy is absorbed by people entering its target area who are instantly warmed, without the need to increase the surrounding air temperature. To keep operating costs to a minimum control devices such as movement sensors and time switches are often employed.

Click here for full details of BN Thermic’s halogen heaters

Quartz halogen heaters allow you to heat specific areas within a warehouse or industrial unit

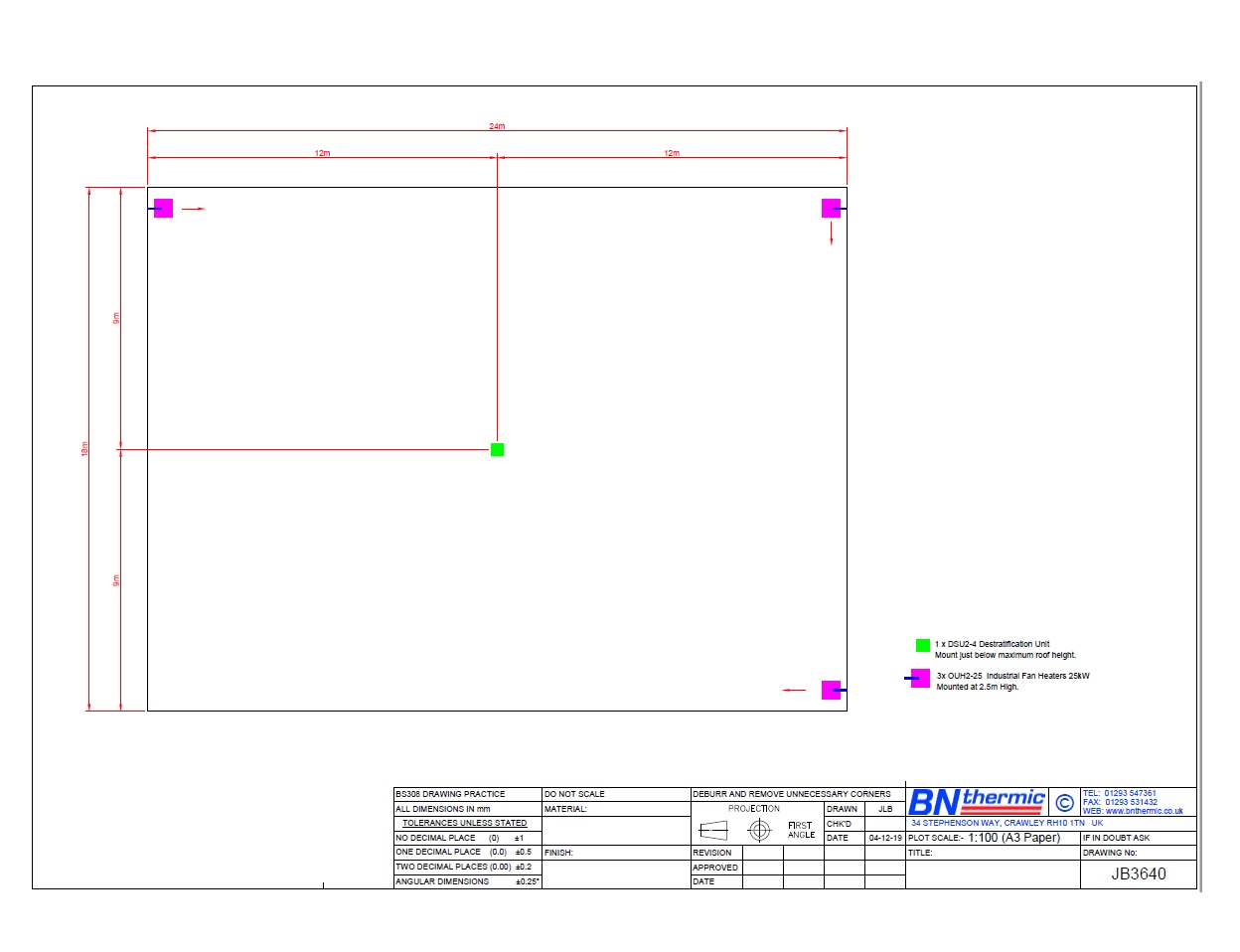

A design for a warehouse measuring 18 x 24m. Three heaters (purple) and one destratification unit (green) were specified

Designing a Warehouse Heating System

Warehouse heating systems, whether using industrial fan heaters or halogen heaters, need to be carefully designed. The engineers at BN Thermic are very experienced and are always on hand to assist. When required, they will visit a warehouse, carry out a survey and provide a bespoke heating proposal. There is a never a charge for this service.

Contact BN Thermic on 01293 547 361 to discuss your project.

- Related: Workshop Heating Solutions

Case Studies

Here are two video case studies where we designed and supplied warehouse heating systems.

In this case study, we specified industrial fan heaters and destratification units to warm a car part manufacturing facility.

In this project, we specified quartz halogen heaters to provide instant heat to an intermittently used warehouse/showroom.

FAQs

-

Warehouses need to be heated either to provide an acceptable working temperature or to protect stored material from the effect of low temperatures. In most cases this is best achieved using large electric industrial fan heaters. Here are some of the advantages of this approach.

- Because each fan heater has a relatively high output, a relatively small number ofheaters will be required thus keeping installation costs to a minimum.

- Industrial fan heaters have high air volume flow rates which provide an even heat distribution through closely spaced racking.

- Electric industrial fan heaters are easy to control economically. If required, they can provide comfort heating during the day and frost protection at night.

The disadvantage of this type of warm air system is that very warm air can collect at high level. This super-heated air is expensive to generate and serves no useful purpose. To combat this phenomenon, we always recommend the use of destratification units in warehouse with roofs above 4m. These devices will effectively recycle this warm air and in doing so, reduce heating bills by up to 30%.